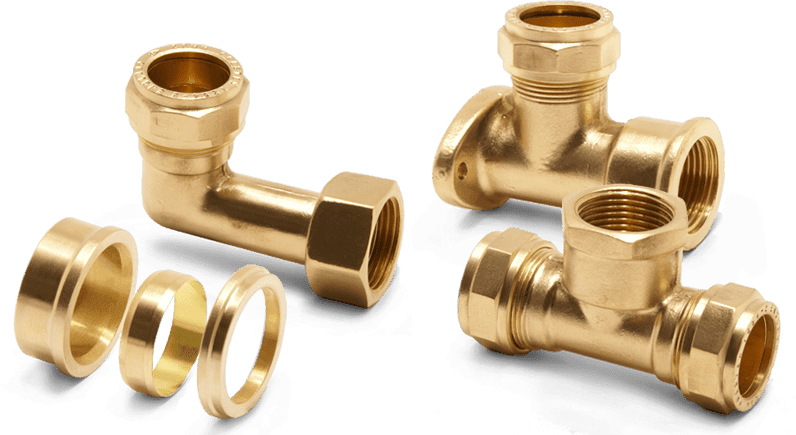

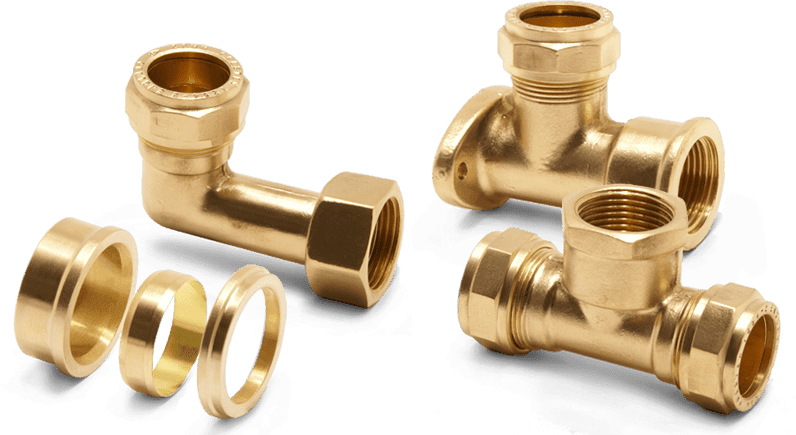

Compression fittings compress one component of the fitting into another component, typically tubing, to produce a watertight seal between two separate lines. The components of compression fittings in the UAE are a sleeve, a nut, and the fitting body itself. All elements of compression fittings collaborate to form a waterproof seal. To make this seal, you must:

- Insert the nut into the tubing

- Slide the sleeve onto the threaded side of the nut

- Insert the tubing into the connection on the fitting body, and then pull the nut and sleeve down until the threads on the nut align with those on the fitting body

- At that moment, the nut is screwed onto the body of the compression fittings

- Utilize the wrench to secure the connection

Compression fittings in Dubai are the antiquated counterpart to quick-connect fittings. While installation of these Pegler Yorkshire compression fittings in the UAE may involve more effort, they nonetheless provide strong, reliable seals for all of your water treatment systems.

Obaid Masood brass compression fittings in Dubai are water delivery system-specific joints for PE pipes. Compression fittings are suitable for use in both irrigation systems and drinking water systems.

Compression fittings are fabricated from numerous materials. Brass is the most common material for compression fittings in Dubai. Additionally, they are frequently made of plastic or stainless steel. Depending on the material or construction of the fitting, the level of pressure or temperature it can withstand will vary.

Obaid Masood’s selection of joints includes a vast array of products suited to satisfy a variety of installation requirements. The leaf joints vary in diameter from d.16 mm to d.110 mm. The threaded joints have a metal reinforcement on the external portion of the thread beginning at r. 1 1/4″.

It is easy to comprehend the amount of pressure a compression fitting can withstand. Typically, a brass connection can withstand greater pressure than a plastic connection. You can find the pressure rating of a fitting online or on the packaging it arrives in. Typically, a compression fitting can withstand 16 bar from d.16 mm up to d.63 mm and 10 bar from d.75 mm up to d.110 mm at 20°C.

Compression fittings are utilized for many purposes. Wherever water lines or air pneumatic lines are connected, compression fittings in the UAE are utilized. If you are only connecting drinking water systems, you will likely employ a quick-connect or quick-disconnect fitting.

The angle stop below your sink is an illustration of a compression thread. Typically, these flex lines use compression threads to connect, for instance, to a coffee brewer.

Because they require no special tools or equipment for installation, compression fittings are generally the best option for plumbing. These pipes may be installed using a crescent wrench, which is essential for working in confined spaces where other wrenches won’t fit.

Obaid Masood is a well-known compression fittings supplier in the UAE with a focus on a variety of plumbing solutions. We also provide UPVC drainage pipes and fittings, Terrain fittings, PEX pipes and fittings, and PPR pipes and fittings.

Compression fittings are utilized for many purposes. Wherever water lines or air pneumatic lines are connected, compression fittings are utilized. If you are only connecting drinking water systems, you will likely employ a quick-connect or quick-disconnect fitting.

The angle stop below your sink is an illustration of a compression thread. Typically, these flex lines use compression threads to connect, for instance, to a coffee brewer.

Because they require no special tools or equipment for installation, compression fittings are generally the best option for plumbing. These pipes may be installed using a crescent wrench, which is essential for working in confined spaces where other wrenches won’t fit.

Click to view List of Compression Fittings