Check valves play an important role in maintaining the smooth operation of any plumbing system, yet we often ignore them. Check valves if used properly can help enhance the performance of any water system.

In this article, we will be discussing the application and type of check valves.

What are check valves?

Check valves are liquid control devices that limit media flow in a pipe system to one direction. It can be attached to either end of the pipe and it will act as a one-way valve that opens when pressure is applied. While water can pass through the check valve, it cannot return through it.

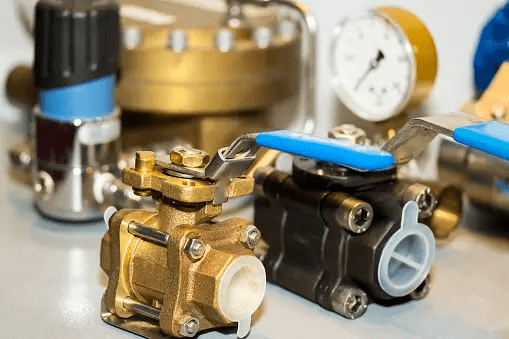

Check valves are available in a variety of sizes, designs, and materials, everything collectively affects the component’s efficiency.

Applications

Preventing fluid mixing

A check valve is used in systems such as water treatment plants due to its ability to keep different fluids separated. Check valves prevent reverse flow, hence stopping the mixing of various media between two reservoirs.

Preventing drainage

Usually, when the pump is halted while media is being pumped from a suction reservoir to a discharge reservoir, reverse flow is quite likely to happen. This is avoided by the installation of check valves. The foot valve is the most typical type of valve used for this.

Protection of upstream equipment

Backflow of fluid can be quite damaging for metres, pumps, filters, compressors, and other equipment designed for one-way flow. Check valves can help reduce the impact of fluid flow on this equipment, preventing damage to them.

Types of check valves

Depending on the application and place of use, the kind of check valve to be applied also changes, here are some of the most common types of check valves used in the plumbing industry:

Swing check valve

The swing check valve consists of a disc that is hinged to the valve body at one edge. When enough pressure is applied to the fluid entering the valve, it presses the disc open, enabling flow. When the flow is reversed or the pressure is reduced, the disc shuts off.

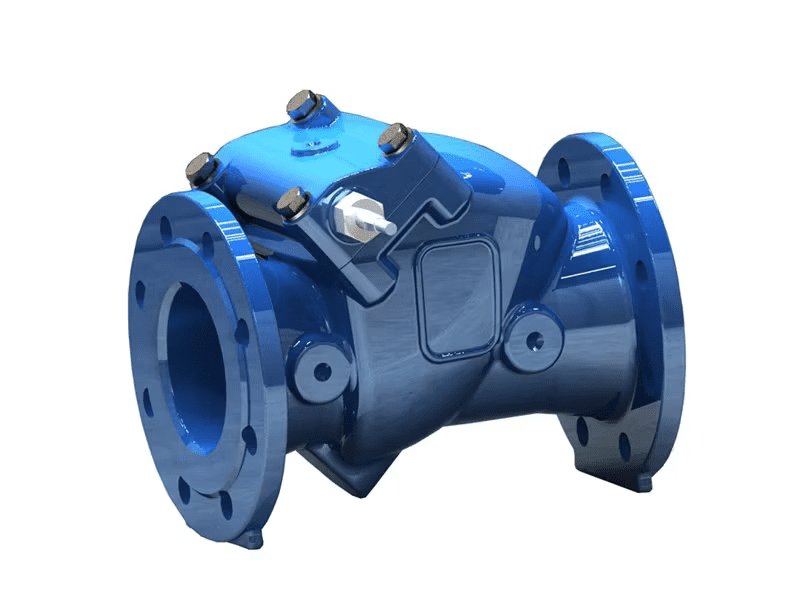

Tilting disc check valve

These double-eccentric disc-built valves are often made to be mounted between two flanges. These valves require high pressure to operate, therefore they are suitable for large-diameter flow. It is advised to not use these valves in wastewater systems as debris can become lodged in the parts of the valve that are in the flow path.

Ball check valve

Ball check valve uses a ball as a closing mechanism. The ball is lifted out of its seat and into a designated chamber by the inflow pressure. The ball goes back to its original position when the inflow pressure decreases, stopping the flow and preventing reverse flow. It is best applied as a sewage check valve.

Foot valve

In order to keep water from leaking in the instance of a pump failure, foot valves are frequently employed in water pumping lines. They are mounted in the suction line of the pump and typically have a screen that removes trash from the reservoir which makes it excellent for pump reservoirs.

Conclusion

If the correct type of valve is used for the right application check valve can smoothen out the functioning of the plumbing system but it can be rather difficult to determine the best choice when you have so many options and little guidance. Obaid Masood is here to help you with this, contact us for any kind of doubt regarding check valves.