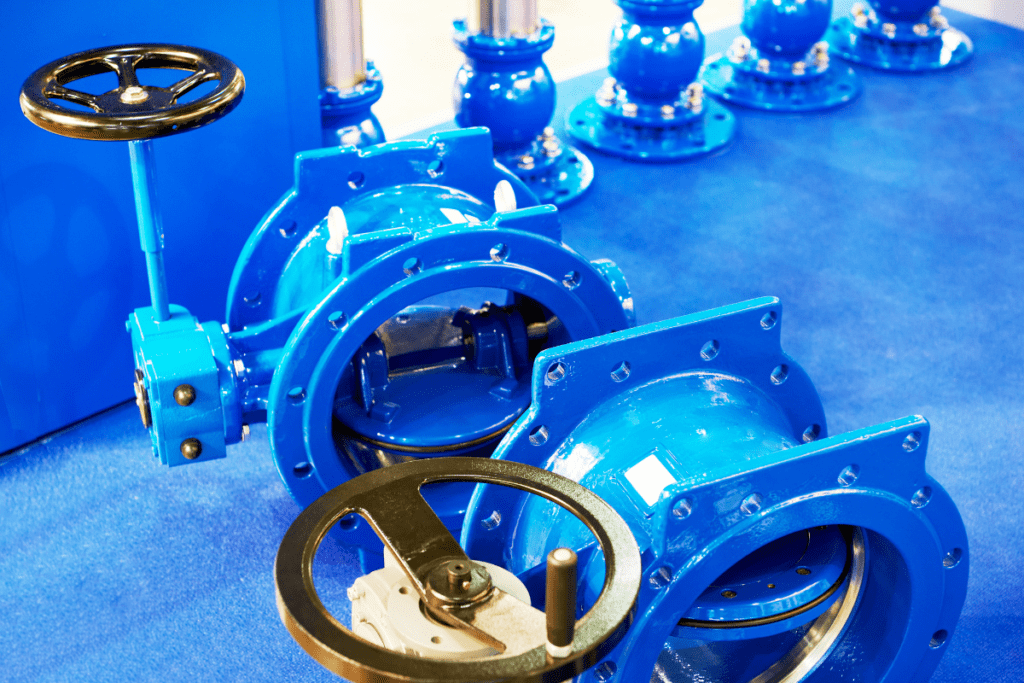

Precision fluid and gas flow management is made possible by high-performance butterfly valves, which play a crucial role in industrial systems. These valves’ portability, quickness of operation, and other features make them useful in many contexts. Selecting the appropriate valve type, size, and actuator is essential for peak system performance, prioritizing routine maintenance, and correct installation. Here are five must-know tricks for optimizing your system with various high-performance valves so that your industrial processes run more smoothly, reliably, and affordably.

Choosing the Appropriate Valve Design

Choosing the suitable high-performance butterfly valve for your system is a critical first step before you can begin optimizing your system. There are a few different layouts for high-performance butterfly valves, the most common of which are concentric, followed by double-offset, and finally, triple-offset. Many distinct types are available, each with its own uses and optimal settings.

- Concentric Butterfly Valves: These valves are a cheap and easy way to control the flow of generally clean fluids in low-pressure systems.

- Double-Offset Butterfly Valves: Double-offset valves enhance performance in systems containing somewhat corrosive or abrasive media and are ideal for low and moderate-pressure applications.

- Triple-Offset Butterfly Valves: Because of their resistance to high temperatures and pressures, they can help with critical systems that transport corrosive or abrasive fluids. Their ability to be precisely controlled and shut off makes them a good fit for rigorous tasks.

Valve Sizing Preciseness

Valve sizing is critical for minimizing frictional losses, avoiding pressure drops, and maximizing the system’s efficiency. Both undersized and oversized valves have the potential to cause problems with flow and control. Valve sizing is crucial to system performance because it allows consistent and efficient control of fluids or gases. You can determine the appropriate valve size for a given application by considering the flow rates, pressure requirements, and fluid qualities.

Regular Maintenance and Inspection

If you want your systems to last as long as possible and perform at their best, routine maintenance and inspections are essential. Inspect and service high-performance butterfly valves and other parts regularly to discover problems before they cause downtime and repair costs. This preventative maintenance ensures that your systems run smoothly, efficiently, and reliably to meet the needs of your industrial processes by lubricating moving parts and checking for signs of wear and corrosion.

Choosing Actuators and Combining Control Systems

The actuator you select will significantly affect your valve’s functionality and responsiveness. Actuators can be pneumatic, electrical, or hydraulic, each with benefits. When choosing the actuator, consider control accuracy, response time, power availability, and safety needs.

Integrating your valve control system with the automation of the whole process can also boost productivity. Your system will adapt quickly to changing operating conditions and retain accurate control thanks to the modern control system’s improved monitoring and adjustment of valve positions.

Accurately Mounting and Placing

The effectiveness of high-performance butterfly valves depends heavily on how and where you install them. Incorrect installation can lead to leaks and premature wear of valve parts. When installing a valve, adhere to the manufacturer’s specifications for everything from sealing methods to torque levels.

Valve placement is just as crucial as the rest of the system. Do not install valves near abrupt bends or elbows to prevent turbulence and pressure drop. Instead, ensure the pipe is straight before and after the valve.

Conclusion

Selecting the best high-performance butterfly valves for your system requires attention to detail in the selection, sizing, maintenance, actuator integration, and installation. These five guidelines can improve your industrial system’s effectiveness, dependability, and functionality. It has the potential to boost productivity and cut down on overhead expenses. Consult valve manufacturers and specialists to make well-informed judgments tailored to individual needs. When appropriately used, high-performance valves can significantly aid in the smooth running of your system. To know more info, Contact us today!