A new generation of stronger, lighter, and more environmentally friendly building materials is on the horizon to resolve the construction industry’s most critical matters. Due to natural catastrophes, high prices, environmental concerns, and inefficiency, the sector struggles to sustain production while keeping up with demand. Building projects absorb fifty percent of our natural resources, often resulting in increased prices, prolonged building delays, and material waste.

To overcome some of these obstacles, several inventive companies are creating a new generation of building materials. Engineers are creating materials that are smarter, stronger, self-sustaining, sleeker, and more environmentally friendly.

Self-repairable concrete

Concrete’s popularity in the construction sector is sometimes surpassed only by the regularity with which it breaks. Cracks, repairs, leaks, and the need for damp-proofing would be eliminated with self-healing concrete, which would be a windfall for the construction sector. Surprisingly, the concept of self-healing concrete has existed since ancient Rome, when it was utilized underwater, although contemporary ways are far more advanced.

Self-healing capabilities are provided by Bacillus bacteria, which are mixed with concrete prior to placement. When a fracture forms, limestone is produced to fill the void. Since the bacteria can remain latent for up to two centuries, this is also a rather long-term cure.

Hardwood cross-laminated timber

Cross-laminated timber, which consists of layers of solid wood, has shown to be a key option for constructions requiring sustainability and longevity. Its alternating, layered architecture makes it almost as strong as reinforced concrete and structural steel, and it could potentially be utilized in the same manner as these materials in similarly designed buildings.

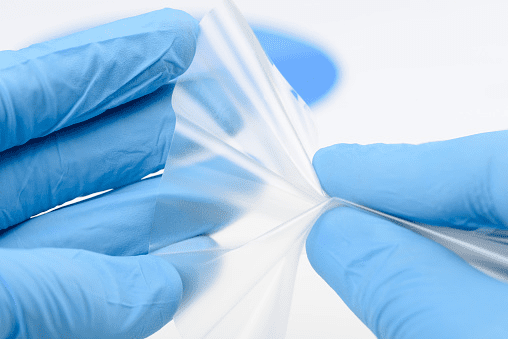

Bioplastic

Due to its molasses-slow biodegradation process, plastic, which is very durable and long-lasting, is also one of the world’s most polluting substances. Bioplastic, which is composed of algae, marine chitins, cellulose, and a multitude of other renewable biomass resources, degrades significantly more rapidly after being discarded. Its advanced qualities make it an ideal alternative to plastic manufactured from fossil fuels for use in cladding, structural components, and other architecture-enhancing constructions.

Homeostatic facades

We’ve all worked in places where the environment, such as temperature or excessive light, can become oppressive over time. The concept behind homeostatic facades is that the material they are constructed from adapts to the outer circumstances to provide the best inside settings.

Composed of a dielectric material (a polymer that responds to electric impulses) ribbon encased in a double glass facade, both sides are coated with silver, which reflects light and distributes electricity across the material’s surface, allowing it to adapt to the building’s most essential conditions.

Mass Timber

The usage of wood in commercial building projects has significantly declined over time. Due to their strength and fire resistance, concrete and steel have been the favoured materials. However, mass timber is basically solid wood that has been laminated and panelized to boost strength and longevity.

Using mass wood allows builders to minimize the carbon footprint of buildings by sequestering carbon from the environment and saving money on construction materials.

3D-printing of graphene

Graphene, regarded as one of the world’s toughest synthetic materials, has physical features that enable its possibilities almost endless. However, since it physically emerges as sheets or particles, its usage in the building becomes challenging (though not impossible).

The idea of employing 3D-printed graphene in construction was reinforced by a report released by three MIT engineers that described a three-dimensional structure that, if constructed using 3D-printed graphene, could be 10 times as strong as steel while weighing just 5% as much.

Aerographite

Aerographite was invented in 2012 by researchers at the Hamburg University of Technology. It is composed of networks of hollow carbon tubes, making it 75 times lighter than Styrofoam. It is stable at room temperature, conducts electricity, is extraordinarily strong, and can yet be shaped into different forms.

In fact, it is so flexible and pliable that it can be compressed into a space 95% the size of its typical area and then returned to its original shape without being damaged. Aerographite, unlike most lightweight materials exposed to compression, becomes stronger when compressed. Since it is also resistant to vibrations, it is often employed in aircraft and satellites.

Obaid Masood, a building material supplier in UAE can guide you in establishing a modern and efficient workplace. For further information about our services, please visit our website or contact us at +971 52 7908123.