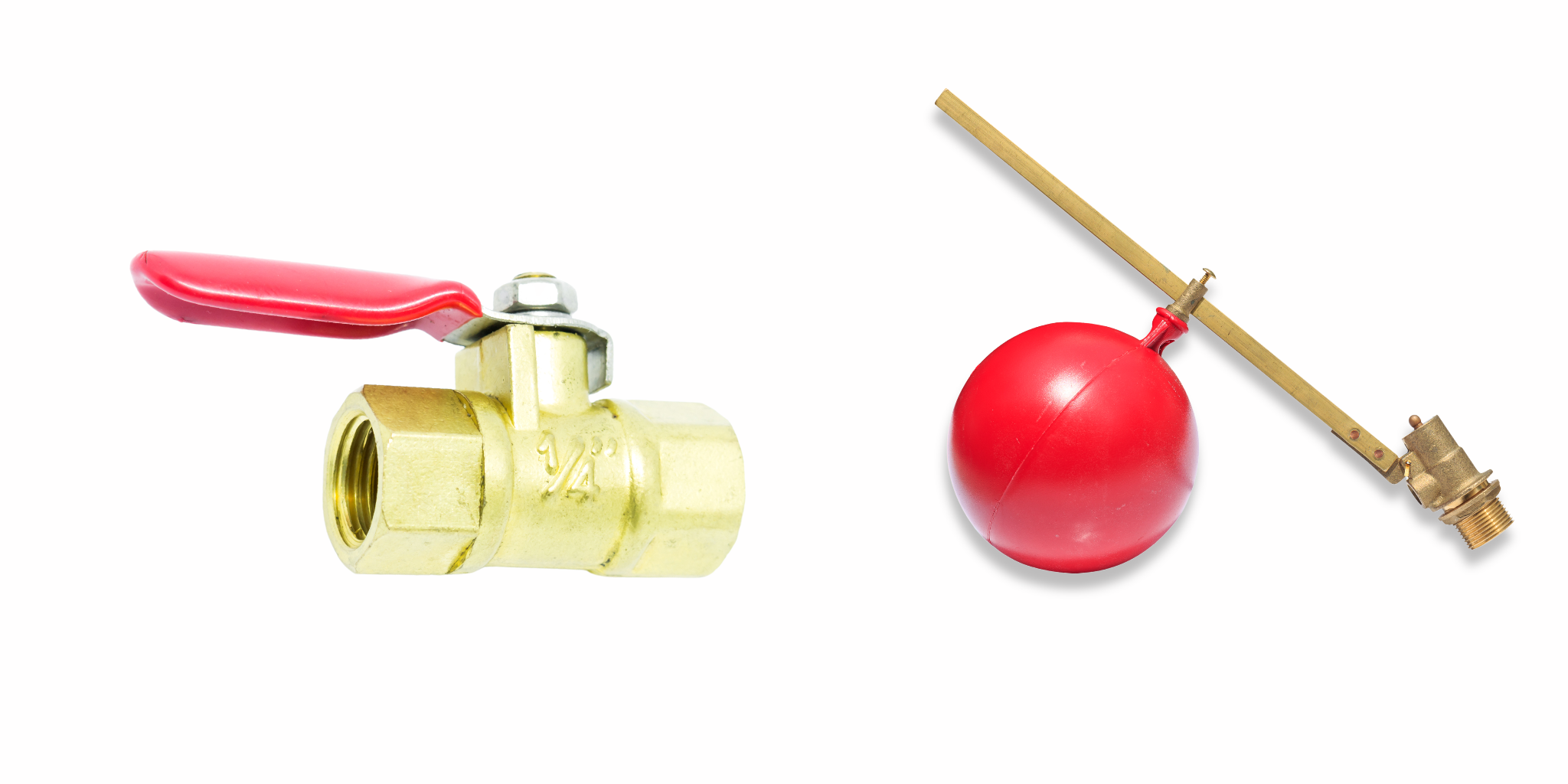

Do you think float valves and ball valves are the same? Though they are similar, there are many differences.

Many people are unaware of them. This blog post clarifies the concept of these two valves and the difference between them.

About the Ball Valve

A ball valve is a quarter-turn valve that controls the flow of liquids using a hollowed-out, perforated, pivoted ball. When this valve is opened, the port or hole in the middle of the ball will be aligned with its entrances and exits. You must rotate the ball by 90 degrees whenever closing this valve to stop fluids from going through.About the Float Valve

Float valves, often called float-operated valves, control the liquid level in reservoirs or tanks. They consist of a floating component that moves up and down with the liquid level. This part regulates the valve’s opening and closing according to the predetermined level, allowing for automatic filling or halting.4 Major Differences Between Ball Valve and Float Valve

Functionality

- Ball Valve: Ball valves are mostly used to control the flow of liquids on and off. They allow exact control over when the flow starts or stops, much like a switch for liquids. Because of this, they are perfect for applications where precise and fast flow regulation is required.

- Float valve: Made to keep the liquid level in a tank or reservoir consistently high. It guarantees that the liquid maintains a constant level by using a float’s buoyancy, avoiding overflow or depletion. Because of this, float valves are used in systems like cooling towers and water tanks where keeping a constant level is critical.

Mechanism

- Ball valves allow or restrict liquid flow by rotating a spherical ball. Because they have simple and effective mechanisms, they are used to manage fluid flow in pipelines, plumbing systems, and other industrial activities.

- Float valve: This type of valve opens or closes based on the buoyancy of a float. The float moves in response to changes in the liquid level, opening or closing the valve.

Application

- Ball Valve: Ball valves are widely employed in pipelines, plumbing, and industrial systems where managing the correct flow with extreme precision is a must.

- Float Valve: It is applicable in water tanks, cooling towers, and irrigation systems where liquids must be leveled to form consistency.

Maintenance

- Ball Valve: Ball valves are known for their durability and typically require little upkeep. They can withstand high pressures and temperatures with minimal damage, making them perfect for industrial settings that demand less upkeep.

- Float Valve: Float valves require a good degree of maintenance because they are exposed to fluctuating liquid levels and the possibility of debris accumulation. Routine examinations are important to guarantee optimal operation and avoid problems like clogging or leaks.