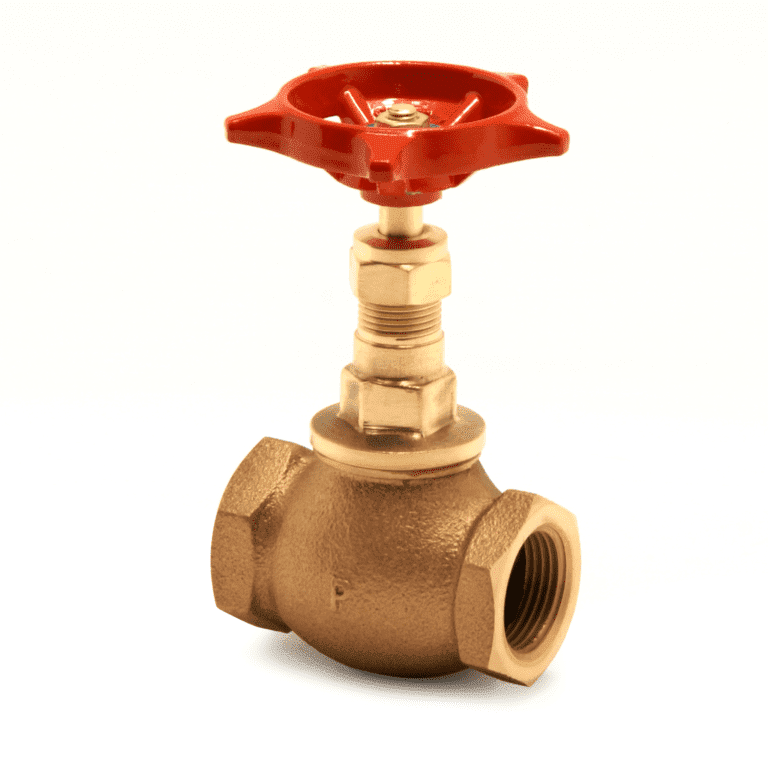

Globe valves are linear motion closing-down valves that are used to start, stop, or regulate flow using a disc as the closure element.

Globe valves in the UAE are ideally suited for restricting and regulating fluid flow and are typically utilized in small-diameter pipelines. In general, globe valves in Dubai are utilized for pipes with a diameter of 8 inches or less.

The following are the parts that make up typical globe valves:

- Globe valve body: Globular shape

- Bonnet

- Disc or Plug

- Stem

- Yoke

- Gland bushing and flange

- Seat ring

- Yoke Sleeve

- Gland Bolts and Nuts

- Handwheel: Mechanical Actuator

- Back Seat

- Pressure Seal Gasket

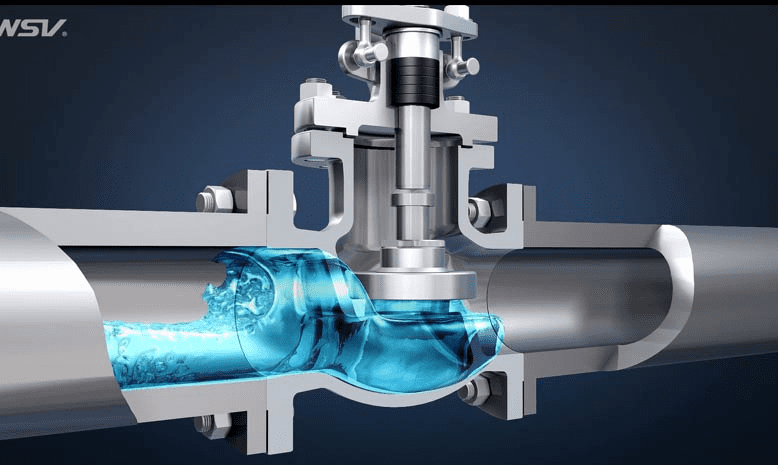

- Packing

In a spherical body, globe valves contain a rotating disc and a fixed ring seat. The seat of a globe valve is centered and parallel to the pipe, and the disc seals the opening in the seat. The valve stem regulates disc movement (lowered or elevated) when the handwheel is manually or automatically spun. When the disc of the globe valve abuts the seat ring, the flow is totally halted.

- Superior stop compared to gate valve

- Good for continuous use

- The seat and disc may be accessible from the valve stem, making repair simple

- Operates more quickly due to its shorter stroke length

- The automated actuator controls the operation of the device

Applications of globe valves

- Globe valves in Dubai are utilized in systems where both flow control and leak tightness are essential.

- It is utilized in high-point vents and low-point drains when safety and leak-tightness are of the utmost importance.

- It can be used in feedwater, chemicals, air, lubricants, and nearly all other services where pressure drop is not a concern.

- This valve can also be used as an automatic control valve.

- T- type globe valves have the lowest flow coefficient and the highest pressure drop of all valve types. Such globe valves can be employed in applications requiring severe throttling.

- Y-type globe valves can be cracked open for extended periods of time without experiencing serious degradation. They offer relatively low flow resistance.

- Angle valve: Without the use of an elbow, these globe valves guide the fluid flow in a perpendicular direction. Because of their capacity to withstand the slugging effect, globe valves in Dubai of the angle type are employed for pulsing flow services.

Numerous varieties of globe valves are intended to accommodate a wide array of tasks at the lowest possible cost. The three most prevalent configurations of globe valves available for industrial usage are:

T- type globe valves have the lowest flow coefficient and the highest pressure drop of all valve types. Such globe valves can be employed in applications requiring severe throttling.

Y-type globe valves can be cracked open for extended periods of time without experiencing serious degradation. They offer relatively low flow resistance.

Angle valve: Without the use of an elbow, these globe valves guide the fluid flow in a perpendicular direction. Because of their capacity to withstand the slugging effect, globe valves of the angle type are employed for pulsing flow services.

The globe valve has a high capacity for sealing. OBAID MASOOD provides a large variety of globe valves for different applications.

If the flow resistance from the convoluted flow route of these valves is acceptable, they can be employed for on-off duty. Some globe valves are also built with low flow resistance for usage in on-off applications