Valves are crucial in regulating the movement of fluids and are, hence, indispensable in a wide range of industries. Butterfly valves and ball valves are two control valves that are often utilized. Both are useful in their own right, but each has its quirks that make it better suited to particular jobs than the other. In this post, we’ll compare and contrast ball and butterfly, two common control valves.

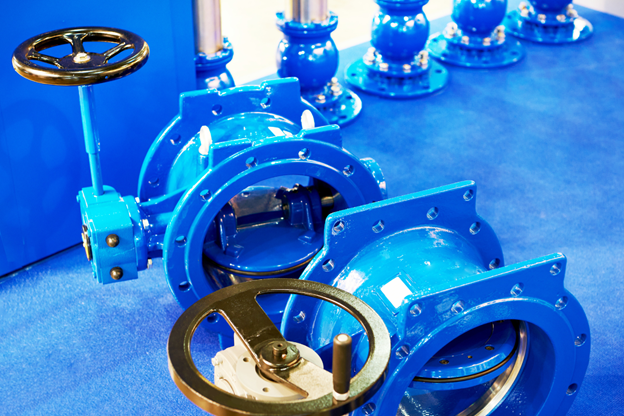

Butterfly Valves

- Conception and Function The disc of a butterfly valve is shaped like a butterfly’s wings, thus the name. The disc in these valves is generally round and pivots around a central axis within the valve body. You can adjust the flow by rotating the disc in a parallel or perpendicular direction to the flow direction.

- Regulating Flow The precise flow control offered by butterfly valves is one of their benefits. By shifting the disc’s location, users can control the flow precisely, making them useful in situations that require a wide range of pressures and volumes. However, they are less effective than ball valves at providing a secure seal.

- Size and Mass Because of their smaller size and lower weight, butterfly valves are frequently used in place of ball valves, where these factors are critical.

- Cost-Effectiveness Compared to their ball valve counterparts, butterfly valves are often less expensive. Its low cost is a significant selling point for projects on a tighter budget.

Ball Valves

- Construction and Function The principal control element of a ball valve is a spherical ball with a hole through the center, thus the term “ball valve.” By rotating the ball within the valve body, we may fully open or close the passageway and regulate the flow.

- Regulating Flow Ball valves are excellent for providing a tight seal. When the ball valve is fully closed, it forms a leak-proof seal that prevents liquids from leaking. This quality makes them superb for use in industries where leakage is a significant issue, such as the oil and gas sector.

- Durability Ball valves are well-suited to high-pressure and high-temperature environments due to their longevity and dependability. They’re durable enough to work for a long time in various settings.

- Maintenance Ball valves are more difficult to maintain than butterfly valves, but they offer superior durability. Replacing the ball and the seats might be more difficult and expensive.

How to Pick a Valve?

When deciding between a ball and butterfly valve for use in control applications, there are several considerations.

- Determine if a tight shutdown or accurate flow control is more critical for your application.

- Check the installation site for weight restrictions and available space.

- Think about how much money you can spend and how much each valve type will save you.

- It is essential to consider the pressure and temperature of the surrounding environment while choosing a valve.

Conclusion

When it comes to control applications, valves like butterfly and ball, each have their own set of benefits and drawbacks. Ball valves are the gold standard for shutdown and longevity, whereas butterfly valves shine for precise flow control and inexpensive cost. The requirements of your project will determine which valve is most suited to your needs.

Visit OMBMT LLC or call +971 4 3338123 or +971 52 7908123 to learn more about their valve solutions. In addition, you may send an email to pranay@ombmt.com. They know everything about valves and would gladly advise you on which is best for your control system.